Sustainability in Construction: Project Showcase

As part of our series celebrating sustainable construction careers, we look at some of the environmentally-conscious projects that our Go Construct STEM Ambassadors have worked on.

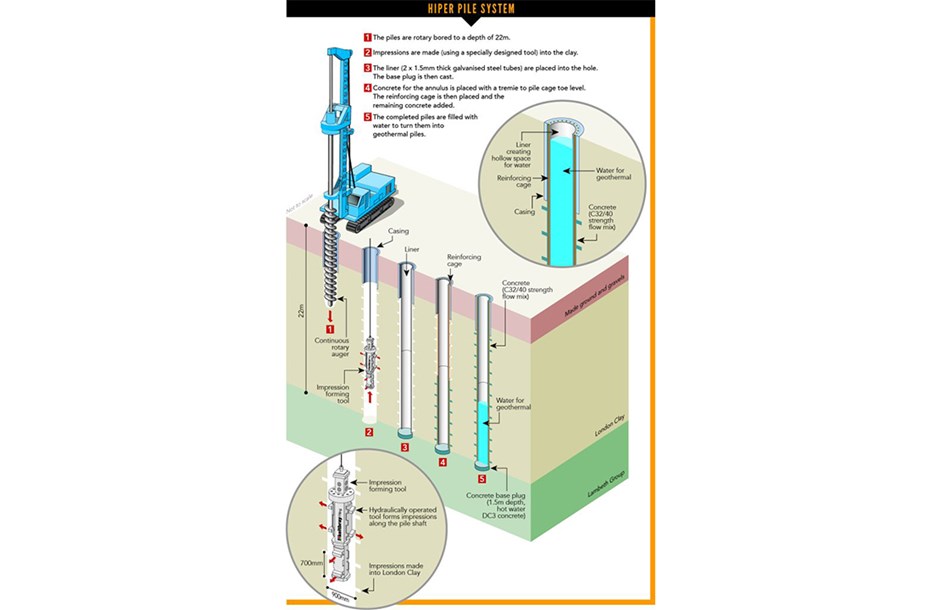

The Keltbray HIPER® Pile

Asha Panchal is a Technical Manager at the civil engineering company Keltbray, and also a STEM Ambassador for Go Construct. Since she joined the company in 2020 she has been involved in developing a pioneering low-carbon piling technology for Keltbray, which has been used as part of the HS2 infrastructure project. Here she explains more about what it does and why it is important for improving sustainability in construction.

What is the HIPER® Pile?

Put simply, the HIPER® Pile is a low-carbon way to lay foundations by using piling, but it also contributes to lowering the embodied and operational emissions of the building it is helping to construct. Traditional methods of concrete piling are environmentally wasteful, and the HIPER® Pile helps to remedy this. It has been used for the first time on a live site in the building of London offices for Mace Dragados’ staff working on the construction of the new HS2 terminal at Euston.

HIPER® Pile is an acronym

Asha explains more.

H = Hollow

Asha: “By introducing a void through the middle of the pile we can save up to 70% of the volume of concrete normally used.”

I = Impression

Asha: “By forming small impressions carefully positioned along the length of the pile we can increase the friction capacity, which means we can then shorten the pile, again saving the volume of material.”

P = Precast

Asha: “By moving towards off-site manufacture we can manage the quality better, reduce the risk of non-conformances, guarantee delivery, and reduce pile breaking by follow-on trades, all of which help to improve Quality, Health & Safety and Scheduling on site.”

E = Energy

Asha: ”We can turn the piles into heat exchangers and tap into ground source energy at much higher efficiencies than that of deep boreholes. The equipment can also be installed without risk of damage and increases the attractiveness of renewable ground source energy, helping clients to reduce their operational carbon footprint.”

R = Reusable

Asha: “Unlike normal deep foundations which cannot be inspected or checked at the end of the building’s design life, the void through the HIPER® Pile allows such inspection. This encourages the reuse of the foundation. This means that for the first time in piling, we can be part of the circular economy.”

How will this influence green construction?

The big win is that up to 80% of the six-storey Euston building’s heating and hot water needs could be provided using geothermal technology, which would power a ground source heat pump. Although the building itself is only temporary, it could be in use for 10 years and at the end of its life, whatever structure replaces it will benefit from the ground source heat pump significantly reducing operational emissions.

HIPER® Pile key benefits

|

Pile length |

Reinforcement |

Concrete |

|

|

Traditional solid pile |

27m |

22t |

687m3 |

|

HIPER® Pile |

23m |

10t |

405m3 |

|

% saving |

15% |

55% |

41% |

Colwick Fish Pass

Emma Faulkner is a Sustainability Assessor and BIM Controller at Jackson Civil Engineering. She is also a Go Construct STEM Ambassador. The sustainable construction project she wants to highlight is a fish pass on the River Trent near Nottingham. Emma’s company was heavily involved in the project, which was undertaken on behalf of the Environment Agency.

Holme Sluices in Colwick Country Park was opened in the 1950s and acts as a flood barrier for the city of Nottingham. However, it also closes off 60km of the River Trent to migratory fish. Colwick Fish Pass incorporates a series of narrow slots and ascending chambers that allow migrating fish to pass through, such as salmon, lamprey and the critically endangered European eel.

Emma: “It is the largest fish pass in the UK at just over 200 meters long. The project involved clearing the area and then piling and digging the 200 m-long fish pass and installing the equipment needed to operate it. The gate itself is 2m high, weighs more than four tonnes, and was constructed off-site. It was lifted into place in one piece using a 40-tonne crane. Once the fish pass is operational, it will be fully automated.”

How has the approach to sustainability in construction evolved?

Emma: “I think that the industry has realised that it isn't just the projects that we build that need to change, it is the materials, equipment and how we purchase them that have to change as well. I think that how we power our equipment and site compounds will be one of the biggest areas we see new trends and innovations. I know I am already seeing more sites that use electric equipment and solar and hydrogen power and I am looking forward to seeing how this evolves moving forward.”

Upper Garnock Valley Flood Protection Scheme

Matthew McAdam is a Site Agent for the construction and civil engineering company McLaughlin & Harvey, and a Go Construct STEM Ambassador. He has worked on road, bridges, ports & harbour projects. The most sustainable project he has been involved in is a flood protection scheme for North Ayrshire Council.

What was the purpose of this scheme?

Matthew: “The construction of the flood protection installation was to reduce the risk of flooding to the communities of the Upper Garnock Valley in Scotland, and help protect the most vulnerable homes, businesses and local services in the local area.

This project involved building an earth embankment dam approximately 13m high and 300m long, which will impound flood water from the river Garnock behind a dam on agricultural land to the northeast of the town of Kilbirnie.”

The project had a large number of environmental improvements. These included:

- Invasive Species Assessment

- Biosecurity Management Plan

- Management of invasive non-native plant species

- Landscaping

Matthew and his team worked alongside the Scottish Environmental Protection Agency, local landowners, farmers, ecologists and specialists to develop a Pollution Prevention Plan. This included water treatment, avoiding any disturbance to wildlife habitats for birds, bats, otters and fish.

How do you think the industry’s approach to sustainability in construction has changed?

Matthew: “Companies are looking to be more sustainable these days, by focusing on the raw materials and the transport they use. On the Garnock Dam project, for example, we used locally sourced earth instead of concrete. There is a large uptake in the use of recycled aggregates, but this can be an issue for some companies in projects which require specialist testing on the aggregate.”

Become a STEM Ambassador and help to make a difference in construction

As Asha, Emma and Matthew’s stories how Go Construct STEM Ambassadors get to work on projects that are making an impact on sustainability in construction. If you’re passionate about construction and want to encourage the next generation of entrants into the industry, how about becoming a STEM Ambassador yourself?

There are lots of reasons why it is a great thing to do and could help your career too. Find out more about how to register as a Go Construct STEM Ambassador.

Feeling inspired? Discover more about sustainability in construction and green construction careers today…

If you want to learn more about sustainability in construction or discover the different green construction careers, get in touch with Go Construct